Efficient MAAP Transport

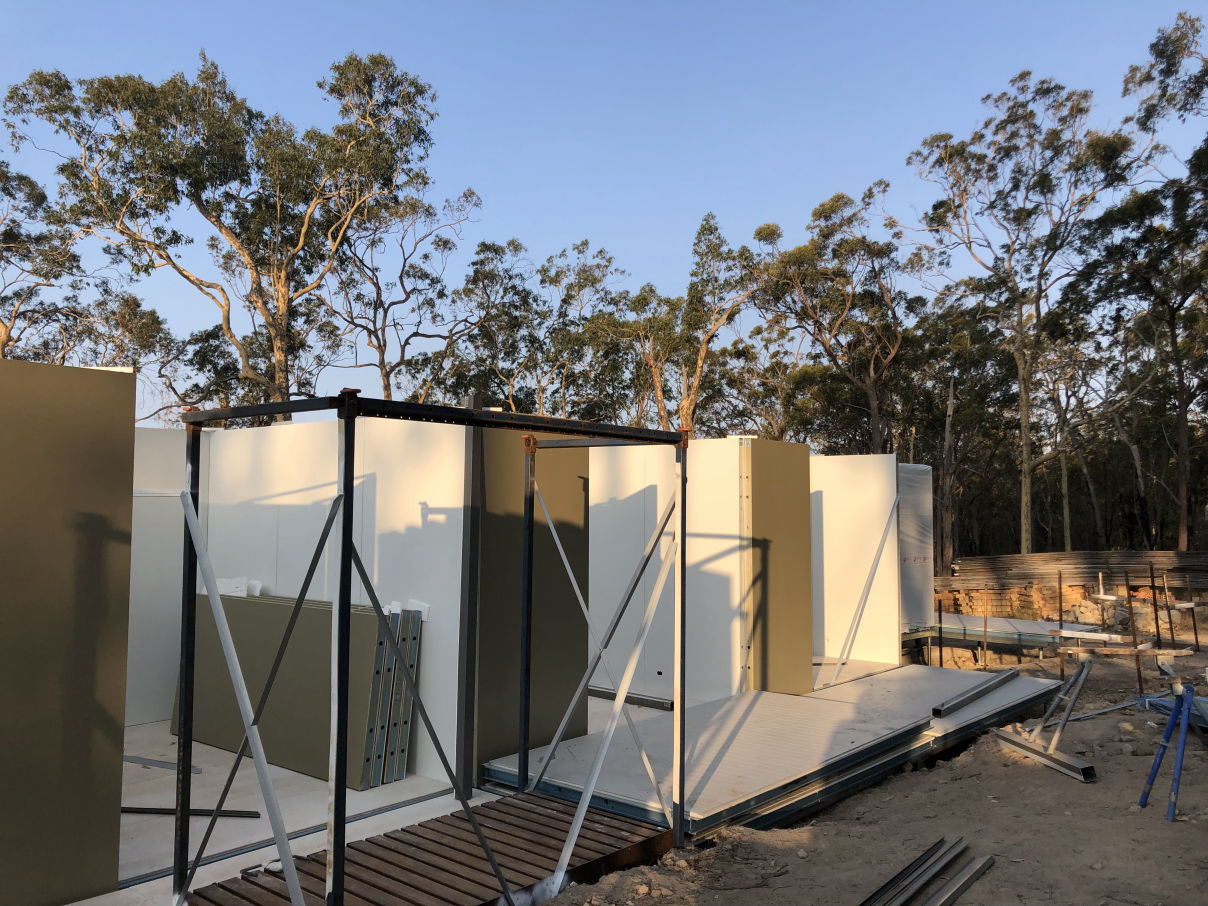

Efficient MAAP Installation

Get an understanding of MAAP technology by watching this time-lapse video of the Merewether on-site assembly.

Patent 2017900829

Contact: MAAP House

info@maaphouse.com

0411 806 499